| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Auten |

| Model Number : | BHD700 |

| Certification : | ISO9001 |

| Price : | Negotiation |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 200 sets/year |

| Delivery Time : | 60 days |

Total 52KW Power CNC I Beam Drilling Marking Machine 2KW Servo Motor Of Drilling Infeeding

Application industry:

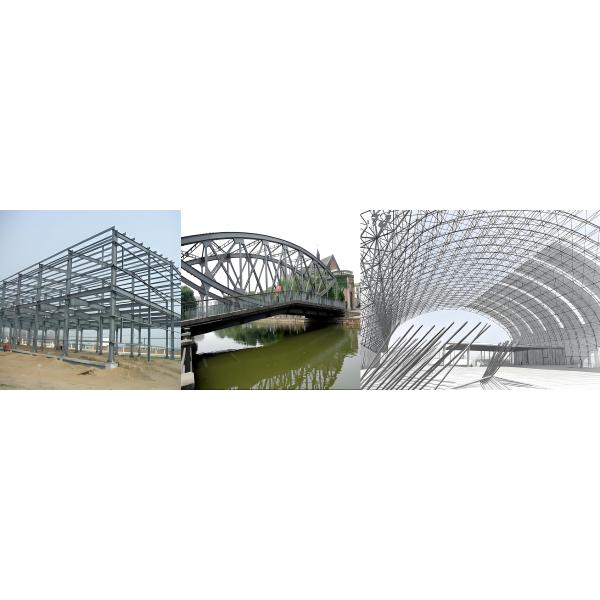

This machine tool is specifically engineered for drilling operations on H-shaped steel. It employs three high-speed precision drilling spindles to conduct workpiece drilling, delivering high machining accuracy and facilitating user-friendly operation. As a core high-efficiency equipment in the steel structure industry, it finds extensive application in construction engineering, bridge projects, tower masts, grid structures, and other associated fields.

Specifications:

| H beam parameter | Max. Size Width x Height | 700×500mm | |

| Min. Size Width x Height | 100×100mm | ||

| Beam Length | 2000~12200mm | ||

| Main spindle | Qty. | 3 | |

| Model | BT40 | ||

| Motor power | 11 kW | ||

| Spindle speed | 100~3000 r/min | ||

| Hole diameter | φ5~φ30 mm | ||

| CNC axis | Servo motor power of X axis | About 5 kW | |

| Servo motor power of horizontal drilling positioning axis | About 1.5 kW | ||

| Servo motor power of vertical drilling positioning axis | About 3 kW | ||

| Servo motor of drilling infeeding | About 2 kW | ||

| Tool magazine | Qty. | 3 | |

| Type | Row style | ||

| Tool magazine capacity | 4 x 3 | ||

| Processing Accuracy | Hole distance deviation | Two holes within 1 meter | ±0.5 |

| The allowable deviation value increases by ±0.2mm for every additional 1 meter of the hole distance, and the maximum does not exceed ±2mm | |||

| End margin deviation | ±1.0 mm | ||

| Machine size | About 33x5.5x3.3m | ||

Components of CNC Drilling Machine Line

The CNC drilling machine line is primarily constituted of core

components, which include a main machine body, a CNC feeding

system, an out-feeding conveyor, a cooling system, a hydraulic

system, a pneumatic system, a lubrication system, an electrical

system, and a waste material cart. This production line adopts a

fixed bed structure combined with a movable workpiece-carrying

structure. The 3D drilling capability enabled by this structural

design facilitates the execution of automated production processes,

thereby supporting efficient and consistent manufacturing

operations.

1. Main Machine Body

The main machine body primarily comprises a base, a bed, a movable

sliding table, a headstock, an upper pressing device, a side

pressing device, and a row-type tool magazine. The bed is

characterized by superior rigidity and stability, enabling it to

withstand the loads and vibrations generated during high-speed

machining processes. This structural performance ensures that the

machine tool’s machining accuracy is maintained consistently

throughout all operational phases.

2. Cooling System

The aerosol cooling method is adopted for drill bit cooling, specifically realized through the combination of compressed air and cooling water. Its advantages include low coolant consumption, enhanced cost efficiency, environmental friendliness, and reduced drill bit wear. A flexible nozzle is mounted on the headstock, and the spray position of the nozzle can be conveniently adjusted—thus ensuring the drill bit is continuously cooled during operation.

3. Lubrication System

This system adopts a hybrid configuration integrating centralized

lubrication and manual lubrication. A centralized lubrication

device is utilized to provide regular and metered lubrication for

specific linear guides and lead screws, while the remaining

lubrication points are maintained through manual lubrication.

This machine tool is specifically engineered for drilling, tapping, and marking operations on H-beams, channel steel, and a variety of other steel workpieces. It supports the machining of steel components with diverse specifications, while guaranteeing high precision and operational efficiency throughout the entire processing cycle. In sample demonstration sessions, for instance, the machine tool can effectively showcase its machining capabilities through standard H-beam samples (with varying flange widths and web thicknesses) and channel steel samples of different dimensions. These displayed samples clearly demonstrate the machine tool’s ability to achieve accurate hole positioning, smooth tapped threads, and distinct marking patterns—fully reflecting its high precision and reliability in practical application scenarios.

The High Speed CNC H Beam Drilling Machine is primarily utilized in steel structure workshops and bridge construction projects. Within steel structure workshops, it carries out precision machining on H-beams applied to frameworks and support structures, thereby laying a solid foundation for the stable assembly of steel structures. In bridge construction scenarios, it performs high-accuracy drilling operations on H-beams—this helps enhance the structural integrity of bridges, enabling them to withstand long-term loads. Its high operational efficiency provides reliable technical support for these critical infrastructure sectors, ensuring the smooth progression of project execution.

|