| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Certification : | ISO9001 |

| Price : | |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 300 sets/year |

| Delivery Time : | 30 days |

| Brand Name : | Auten |

| Model Number : | BHD6060 |

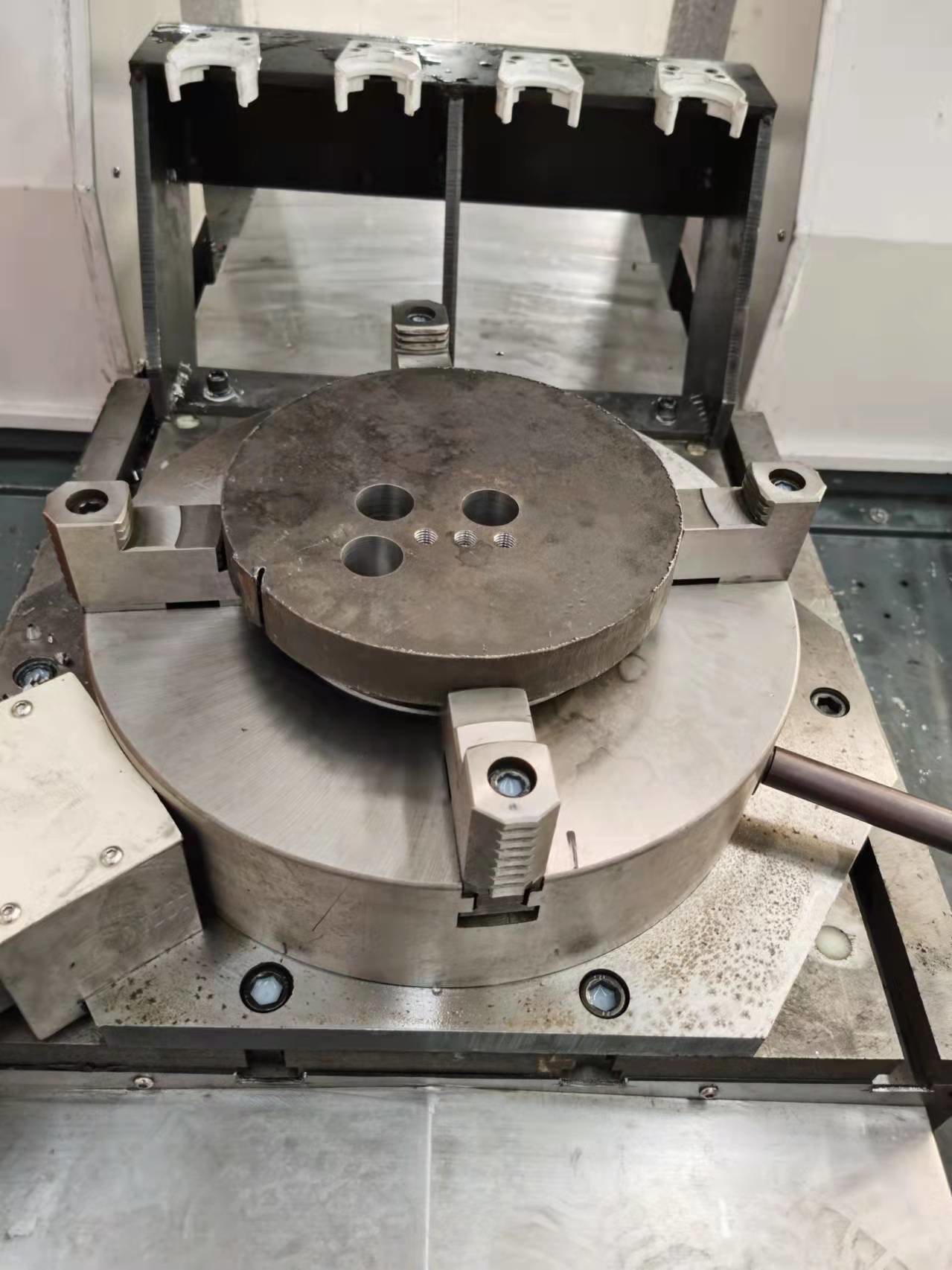

High Speed CNC Flange Drilling Machine for Metal Plates BT40 Spindle

Application:

The CNC gantry drilling and milling machine is mainly used for the drilling, chamfering, tapping, and milling of plate/structural parts with the thickness of flanges, discs, rings, plates and other workpieces within the effective range. Drilling through holes and blind holes can be realized on single material parts and composite materials. The processing process is digitally controlled and the operation is very convenient. It can realize automation, high precision, multiple varieties and mass production.

Equipment structure:

The equipment is integrally cast, mainly composed of worktable, fixed beam gantry, movable sliding saddle, drilling and milling power head, automatic lubrication device, protective device, circulating cooling device, digital control system, electrical system, etc. Rolling hard rail pair support and guidance, precision lead screw pair drive, the machine tool has high positioning accuracy and repeat positioning accuracy.

1,Drilling power head:

The drilling power head adopts a dedicated servo spindle motor, and the geared synchronous belt decelerates to increase the torque to drive the precision spindle. The spindle adopts the first three rear two five-row Japanese angular contact bearings to achieve stepless speed change. The spindle is equipped with a pneumatic tool change system to enable tool replacement Fast and convenient, the feed is driven by a servo motor and a ball screw. The X and Y axes can be linked, using semi-closed loop control, which can realize linear and circular interpolation functions. The spindle end is a BT40 taper hole, equipped with Italian Rotofors high-speed rotary joint, and can use high-speed U-drilling center to discharge water.

2,Automatic lubrication device and protection device

This machine tool is equipped with Taiwan's original volumetric partial pressure automatic lubrication device, which can automatically lubricate various motion pairs such as guide rails, lead screws, racks, etc., without dead ends, and ensure the service life of the machine tool. The X-axis and Y-axis of the machine tool are equipped with dust-proof shields, and splash-proof baffles are installed around the workbench.

Laser interferometer:

The laser interferometer is used to calibrate, and accurately check and compensate the pitch error, backlash, positioning accuracy, repeat positioning accuracy, etc., to ensure the dynamic, static stability and processing accuracy of the machine. Ballbar inspection Each machine uses a British RENISHAW company ballbar to calibrate the true circle accuracy and machine geometric accuracy, and perform circular cutting experiments at the same time to ensure the machine's 3D machining accuracy and circle accuracy.

Specifications:

| Workpiece size | LxW | 600 x 600 mm |

| Gantry height | 400 mm | |

| Drilling power head | Qty. | 1 |

| Spindle taper | BT40 | |

| Max.drilling diamter | Φ35 mm | |

| Max.thickness | 40 mm | |

| Tapping diameter | M3-M15 | |

| Spindle speed | 30~3000 r/min | |

| Servo spindle motor power | 7.5kW | |

| Distance from the lower end of the spindle to the worktable | 200-540mm | |

Lateral movement of power head (X axis) | Max.horizontal stroke | 600 mm |

| Lateral movement speed | 0~9 r/min | |

| Servo motor power for lateral movement | 10N/M | |

| Gantry longitudinal movement (Y axis) | Max. feed stroke | 600 mm |

| Feed moving speed | 0~9 m/min | |

| Feed servo motor power | 10N/M | |

| Vertical ram feed motion (Z axis) | Max. stroke | 400 mm |

| Moving speed | 0~8 m/min | |

| Servo motor power | 1x2.4kW (Brake) | |

| Three-axis positioning accuracy | X/Y/Z/A/B/C | 0-0.02mm |

| Three-axis repeat positioning accuracy | X/Y/Z/A/B/C | 0-0.01mm |

| Machine weight | / | About 3.5T |

| Overall size | LxWxH | 2200x1600x2200 mm |

|