| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Auten |

| Model Number : | AT60 |

| Certification : | ISO9001 |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 200 sets/year |

| Delivery Time : | 60 days |

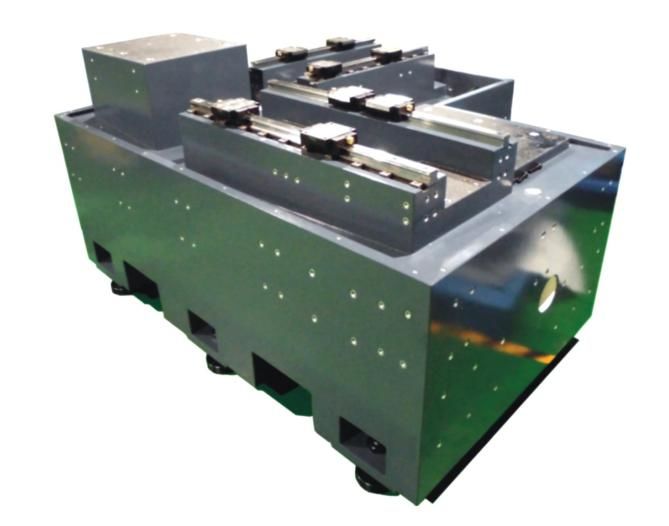

High Precesion CNC Internal and External Circular Composite Grinding Machine Model AT60

Application:

Used for simultaneous grinding of external cylinders or tapered face, end face and internal cylinders, and are suitable for single-piece manufacturing and mass production in the field of high accuracy parts industry.

Features:

■High-precision composite grinding machines are used for simultaneous grinding of external cylinders or tapered face, end face and internal cylinders, and are suitable for single-piece manufacturing and mass production.

■Be equipped with online probe and automatic loading and unloading system.

■ This is designed for gear workpiece, shaft parts, bearings, hydraulic products, as well as the high efficiency grinding for the products of outer circle and inner hole .

Parameter:

| Model | AT-60 | |

Capability | Work range (aperture&depth) | Φ20~φ60x40mm( to φ120mm maximum) |

| Max. grinding diameter | Φ35~φ140mm | |

| Max. grinding length | 100mm(matching to 250mm) | |

| Max. diameter of spindle | 350mm | |

| Max. weight of workpiece | 10KG(able to 150KG) | |

| Grinding wheel spindle form | Independent design for inner and outer diameter | |

Workpiece Spindle | Chuck form | Pneumatic / hydraulic |

| Rotate speed | 1000rpm | |

| Servo motor output power | 3.2KW | |

Internal Spindle | Rotate speed | 20000rpm/36000rpm42000rpm |

| Max. strokemm of X-axis | 310mm | |

| Max. strokemm of Z1-axis | 100mm | |

| Motor output power of X-axis | 3.5KW | |

| Motor output power of Z1-axis | 3.5KW | |

| Specification of grinding wheel | Acc. to inner diameter | |

| Max. moving speed | 10m/min | |

| Min. feed | 0.0001mm | |

| Motor power | 15KW | |

External Spindle | Rotate rate | 3000rpm/12000rpm (acc. To products) |

| Max. range of Y-axis | 210mm | |

| Max. range of Z2-axis | 200mm | |

| Motor output power of Y-axis | 3.5KW | |

| Motor output power of Z2-axis | 3.5KW | |

| Specification of grinding wheel | 400 mm×30mm×203mm / 150 mm×30mm×203mm | |

| Max. moving speed | 10m/min | |

| Min. feed | 0.0001mm | |

| Adjustable angle | 0~12° | |

| Lubricating | Fuel tank volume | 2L |

| Pump motor output power | 0.8KW | |

| Cooling | Filter tank volume | 100L |

| Pump motor output power | 0.075KW | |

Hydraulic System | Fuel Tank volume | 60L |

| Output power | 2.2KW | |

| Outlook | Size(L×W×H) | 2100mm*2500mm*2000mm |

| Weight | 7500Kg |

Marble bed

■The bed of whole series of products are all made of marble.

■There are the advantages such as good vibration absorption performance , intensive to cold and heat, strong integration performance , with stability, environmental protection and energy saving, and so on.

Test

▪High-precision on-line detector system is adopted

▪ The outer and inner diameter can be measured online simultaneously

▪ The workpiece that can be calibrated and measured

▪ Zero and reference points can be set for subsequent machining

▪ Reduce non-machining time during grinding

▪ Improve the accuracy of parts

System

▪ The most powerful CNC control unit

▪ The whole series of products adopt SIEMENS operating system

▪ SINUMERIK Brand-new SINUMERIK user operating interface

▪ Predetermine movement control to shorten processing time and improve the quality and accuracy of the workpiece surface

▪ It not only reduces the setup time and operation complexity of machine tools, but also makes it easy for operators to view and edit by equipping with a variety of grinding form procedure

▪ Ethernet, USB and flash card storage.

▪ The simplest interactive design, easy to learn, and large storage.

▪ Remote diagnosis and help, background editing function, setting a security password.

Spindle

▪ This spindle is a high-precision grinding spindle made in Switzerland, it is the best choice for the best process design, with the following best quality characteristics:

a. Short preheating time. Easy to operate, convenient maintenance and a wide range of applications

b. Good mechanical properties with durabilities

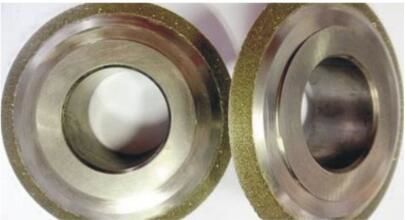

Grinding wheel repair system

High-precision motorized spindle-powered roller-type structural grinding wheel-repairing method, the best choice for high-precision and high-efficiency forming and dressing grinding, is mainly used for dressing internal and external cylindrical CBN grinding wheels, with characteristics of high dressing precision, high efficiency, good straightness, etc. The single point diamond pen dressing method can be chosen.

Lines of business

Workipieces:

|