| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Auten |

| Model Number : | PD4040-2 |

| Certification : | ISO9001 |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 200 sets/year |

| Delivery Time : | 70 days |

| Price : | Negotiable |

CNC Double- Spindle Gantry Movable Plate Drilling Machine Model PD4040-2 Large Metal Plate

Applicable Industry:

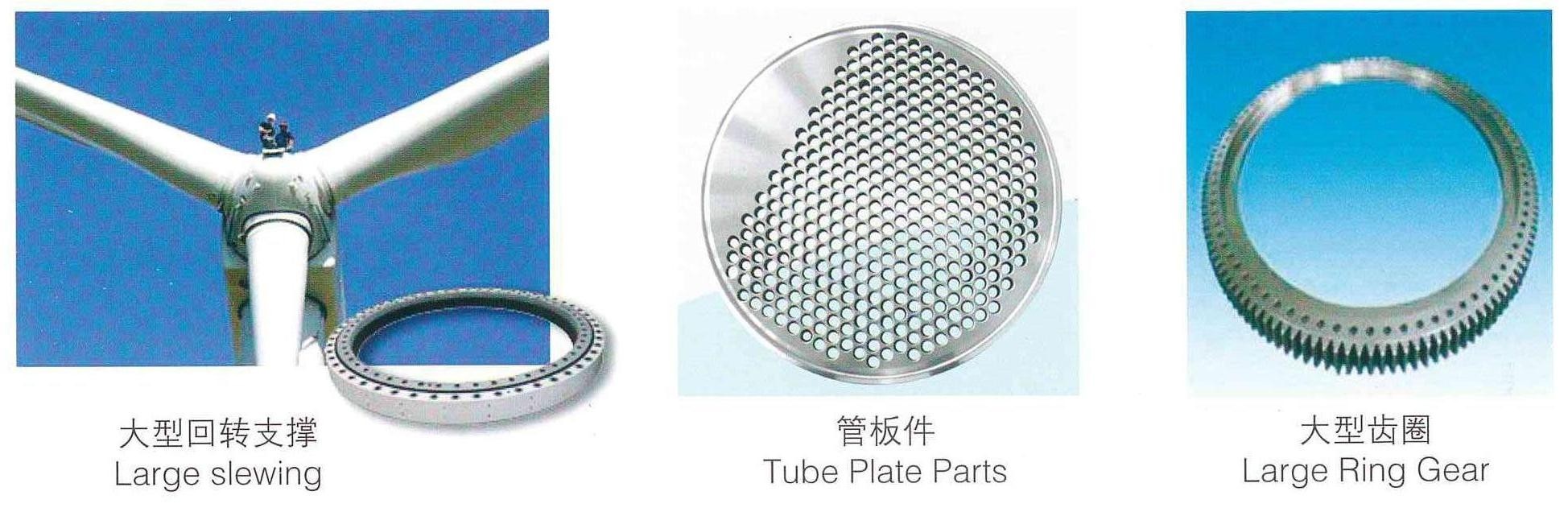

Used for the drilling processing for steel, stainless steel and composite material. It is mainly used for drilling (including blind holes) process of the tube plate, baffle plate in petrochemical machinery, air condenser, heat exchanger etc. and large flange manufacturing, and also for joint plates in building, bridge, iron tower, etc.

This equipment consists of lathe bed work table, movable gantry, longitudinal slide carriage, numerical control slide board, drill power box, automatic chip cleaner and circulation cooling system, electrical system etc.

Product feature:

1. Lathe bed work table

Lathe bed is connected from the left and right main lathe bed and bridge. It is a welded steel structure processed by the artificial aging treatment. A bearing plate is installed on the work table, and a 28mm wide T-groove is made on it for easily placing and clamping workpieces. On the left and right side of the lathe bed, two linear guides with high bearing capacity are equipped respectively for assisting the gantry longitudinal slide carriage guiding. A set of drive mechanism consisting of AC servo motor, ball-screw and screw for gantry longitudinal slide carriage movement, to ensure high precision of positioning and repositioning. M20 adjustable nuts are installed the underside of lathe bed for easily adjusting the level of work table.

2. Movable gantry

Because the lathe bed is fixed while gantry moving, the equipment occupy small area. The gantry is welded by steel plates and processed by the artificial aging treatment. Two linear guides and two NC slide carriage type power heads are installed on the front of the gantry, and a set of transfer mechanism consisting of precision ball screw assembly is installed on the top of gantry. The nuts on the screw assembly are connected with the AC servo motor on the two NC slide carriage by synchronizing wheel and belt. When the AC servo motor on the two NC slide carriage type power head rotates, the NC slide carriage will move along Y axis. So that ensures the precision of positioning and repositioning. Guide flexible protective covers are installed on the two sides of the power head.

3. CNC slide carriage type power head

The power head use servo motor to realize numerical feeding through reducing speed by synchronizing belt and gear, driving vertical ball-screw rotation. During work, the automatic cycle is realized from the process of fast feeding when the drill contact work pieces, changing to automatic feeding after the dill contact work pieces, changing to fast reverse after drilling through and parallel shifting to next drilling position after the drill top leave work pieces back to set position. It has the function of drilling through-hole and blind-hole, automatic chips cutting and discharging etc., so that greatly improves the production efficiency. Drill main motor of drill power head use frequency converter to regulate speed stepless which is easily operated. it is installed Quick change module of Morse no.4 taper hole under the drill spindle, with Morse 3#,2#,1# reducing sleeves, which can install different diameter drill under 50mm.

4. Longitudinal slide carriage

Movable gantry is installed the left and right longitudinal slide carriages, which is right-angle bending plate welding steel structure. A set of transfer mechanism consisting of AV servo motor and high precision ball-screw assembly on the left and right sides respectively. The nuts on the ball-screw assembly are connected with longitudinal slide carriages. When the AC servo motor rotates, it drives the nut to move along the ball-screw(X axis), the slide carriage moves along the guide at the same time.

5. Chip cleaner and circulation cooling system

The equipment uses one set of picking chip box type chip cleaner, which is installed in the movable cooling water tank fixing with cooling pump. The pump is used for providing coolant liquid for cooling spindle dill. The exit is connected with the sprayer fixed on power head side by hose in drag chain.

6. The positioning, alignment and clamping of work pieces

For square work pieces, alignment can be realized by fixing two direction reference blocks on the bearing plate with T-groove. For round work pieces, alignment can be realized by putting the work piece any place on the bearing plate with T-groove, then the edge finder installed in the spindle taper hole will calculate the center automatically by NC program after measuring any three points of the work piece(inner or external diameter). It is fast and precise. The work pieces are clamped by pressing plate, pull rod and

setting blocks. It is very convenient to operate.

7. CNC system

CNC system use Spain FAGOR8055 to control X axis and Y axis. Coordinate setting is controlled by FAGOR8055. Z axis uses Japan Mitsubishi PLC control. It is also equipped with RS232connecter and CRT display. The operation interface has functions of man-machine conversation, error compensation and automatic alarm etc. Processing program can be created automatically by inputting work piece hole position by keyboard and CAD soft ware. it has the function of preview and recheck before drilling, which is easily operated.

Specifications:

| Parameter Name | Item | Parameter Value |

| Max. size | L X W | 4000X4000mm |

| Max. thickness | 250mm | |

| Work table | Width of T slot | 28mm |

| Vertical slide type drill head | NO. | 2 |

| Main spindle taper hole | Morse 4# | |

| Max drill diameter(common carbon steel) | Φ50mm | |

| Main spindle speed | 120—560 r/min | |

| Motor power of spindle | 2 × 5.5 kW | |

| Distance between spindle tip to work table | 200-550mm | |

(X axis) Gantry longitudinal move | Max. stroke | 4000mm |

| Moving speed of X axis | 0-8m/min | |

| Servo motor power of X axis/torque | 2X1.8kW/11.5Nm | |

(Y axis) Power head transversal move | Max stroke | 4000mm |

| Moving speed of Y axis | 0-8m/min | |

| Servo motor power of Y axis/torque | 2x1.8kW/11.5Nm | |

(Z axis) Vertical slider feeding | Stroke of Z axis | 350mm |

| Feeding speed of Z axis | 0-5m/min | |

| Servo motor power of Z axis/torque | 2x0.85kW/5.39Nm | |

| Positioning accuracy | X,Y axis | ≤0.1mm/ Full length |

| Repositioning accuracy | X,Y axis | ≤0.05mm |

| Hydraulic system | Hydraulic pump pressure/flow rate | 6.5MPa /25L/min |

| Hydraulic pump motor power | 3kW | |

| Pneumatic system | Compressed air pressure | ≥0.4MPa |

| Chip cleaning and cooling | Chip cleaner type | Plate chain type |

| Chip cleaner no. | 2 | |

| Chip cleaning speed | 1m/min | |

| Chip cleaner motor power | 2X0.75kW | |

| Motor power of Outer cooling water pump | 0.75kW | |

| Automatic lubricating system | Lubrication pressure | 2MPa |

| Lubrication point oil injecting amount | 0.1mL | |

| Lubrication period | 6-10min | |

| Electric system | CNC system | FAGOR8055 |

| CNC axis NO. | 6 | |

| Whole power of motors | Approx. 35kW | |

| Overall size | LxWxH | Approx. 7200X7050X3200mm |

| Weight | Approx. 30t | |

|